| 用于干燥剂的样品包装湿度卡 |

| 使用静电袋 |

| 样品包装常用哪些工具 |

| 不同类型芯片封装样品的封装方法怎么样 |

| 样本包装问题 |

-原创内容,请勿转载。

样品包装是否应该放湿度卡干燥剂?我应该使用静电袋吗?以及如何封装不同组件封装的样品板?如果样品板包装不当会带来什么后果?今天我们将详细讨论这些问题。

用于干燥剂的样品包装湿度卡

只需几个样品包放入湿度卡和干燥剂中?对于具有高湿度敏感性的电子元件,通常提供以下封装:QFP、PLCC、BGA、CSP、SOP、SOJ、QFN、PGA。如果它们暴露在湿气中,它们很可能会在高回流温度下蒸发和膨胀,从而破坏芯片。但对于产品原型,大多数客户都是手工焊接。但对于产品原型,大多数客户都是手工焊接。所以焊接要求没有散装那么高,所以你可以根据自己的情况来决定。

使用静电袋

• 静电对精密元件的危害不小,它可以穿透元件内部,使元件内部扳机锁定,或短路。

• 在现实生活中,三极管样品经常不使用静电袋似乎没有静电击穿,说明静电击穿是偶发的损伤问题,不是大概率大概率或事件数量多,而是发生的可能性。

• 静电袋的成本不高。为了给产品更好的产品质量保证,哪怕是小概率的事件为什么不去避免它的发生呢?

样品包装常用哪些工具

我们最常见的样品装填工具

• 样品盒、塑料样品盒、纸箱样品盒、内置防静电保护海绵。对于没有托盘或编织带包装的材料,可以加载 1-6 片的样品。

• 样品封口袋、防静电平袋、防静电自封袋、防静电铝箔袋。

• 与封装的托盘相对应的托盘。

• 泡沫袋、防震和防压缓冲泡沫袋。

• 干燥剂、5 克小袋干燥剂、20 克、30 克干燥剂、50 克干燥剂。

• 包装纸箱,样品需要用气泡膜包装,以填充箱内的空白空间,以防止振动或重压对样品的损坏。

How about packaging methods for different types of chip packaging samples

Today, I got these packages to share with you.

QFP

• QFP packaged samples are usually in trays, but also in tape and reel, QFP has a high density of feet and is fragile and brittle, as the samples do not have the original packaging or trays.

• Packing this kind of sample is more difficult, nana think it is best to use this kind of sample special sponge packing box.

• In addition to anti-pressure, anti-friction can also be anti-static, QFP samples are very suitable for, in order to prevent the samples of moisture, placed in the sample box and then vacuum.

QFN

• Tape-and-reel samples can be packaged in anti-static self-sealing bags, or in the anti-static sponge boxes mentioned above.

• QFN package type components are mostly tape and reel mounted.

DIP

• DIP package devices are common tube mounted form, the sample board is not enough to cut down the tube.

• Load the chip and then plug the anti-drop plug to prevent the gap is too large chip back and forth friction damage to the chip.

• Finally, use the anti-static bag to seal.

SOP or SSOP TSSOP

• SOP or SSOP, TSSOP package, usually tape and reel, tape and reel samples can be packaged in anti-static self-sealing bags.

• Some of the tubes can be packed in anti-static sponge boxes, or directly in tubes and then packed into anti-static bags after vacuum sealing.

![1731574244996770.png {3T7J%}2%G$V]5]_$}`T_56.png](/image/ueditor/php/upload/image/20241114/1731574244996770.png)

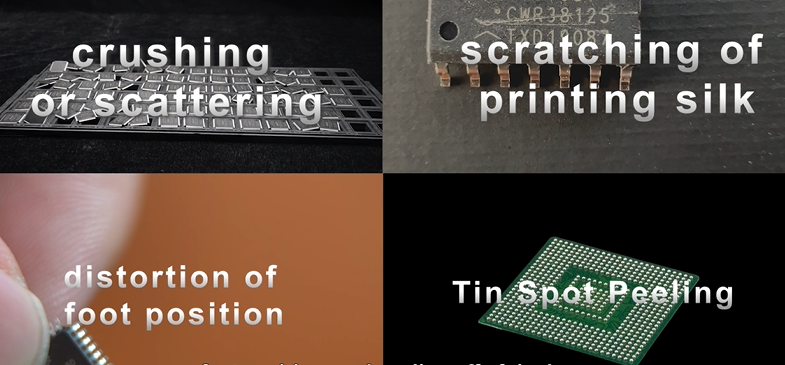

Sample packaging problem

Keep these in mind when packing samples

• Bad packing will lead to friction between goods after crushing or scattering, scratching of printing silk, distortion of foot position, and peeling off of tin dots.

• Braided tape without a disk of goods can not be rolled too tight, too tight will be pressed crooked inside the foot of the foot which leads to goods in the hands of customers can not pass the test.

• Vacuum-packed goods that leak may render the feet unusable after oxidization.