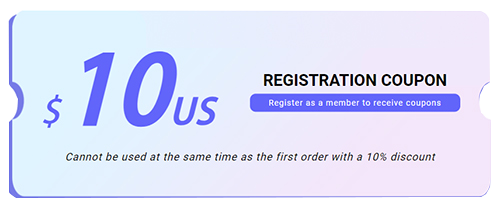

FIRST ORDER

FREE 10% DISCOUNT

Quality Control Programme

Quality is always our main concern

Technically, we give ourselves more challenges.

Implementation, we give ourselves the most stringent requirements.

We are committed to providing customers with the industry's highest quality, standard electronic components, products to directly meet the customer's production needs.

We have strict quality control system throughout every process to ensure the consistency of quality with the original factory, to ensure zero-defect quality management of products.

Counterfeit components methods and management strategies、quality control

Our QC Process

Strictly According to ISO9001:2015 System, ensure the professional reliability of our service and quality.

1st Level Inspection: Basic Inspection

Package Inspection—Incoming Document Verification— Requirement Verification—Digital Photography—Recording and Receiving—prepared for 2nd level inspection.

2nd Level Inspection: Quality Inspection

Parts Label Verification—Visual Inspection—Dimension Checking—Digital photography via X-ray—Perform high-temperature aging testing—Surface & Scrape Test—put parts on Locator Rack with QC qualified label (If the 2nd test cannot be judged, parts will be prepare for 3rd level Inspection).

3rd level Inspection: Foxconn Testing Center

Appearance—Ultrasonic—Electrical—Chemical Element Composition Analysis—Slice—Open The Parts Seal.

The technical team has the following testing capabilities

Importance of requirements, strict appearance and performance testing of each batch of incoming materials.

Test equipment is utilised. Ensure that the device can meet its own specifications performance requirements of its own specification.