| Static electricity damage |

| Anti-static war-Protection of operating space |

-Original content, please do not reprint.

Static electricity damage

• If there are a hundred ways to damage a chip, static electricity is definitely the most insidious one.

• The static electricity generated by human body friction is thousands of volts, and can reach up to tens of thousands of volts, which has exceeded the voltage limit of electronic components.

• When the human body comes into contact with electronic components, static electricity will be generated, and the static electricity generated will damage the components. So what can we do to prevent this?

Anti-static war-Protection of operating space

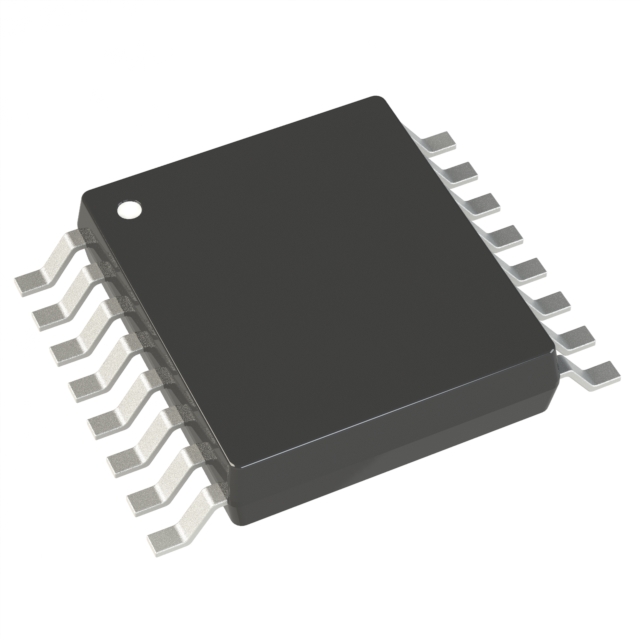

The density of integrated circuits is getting larger, the thickness of its materials is getting thinner , and the ability to withstand electrostatic voltage is getting lower, The components of Packaging requires static protective bags.

• 1:After accessing, the components are stored in static packaging protective bags.

• 2: Packaging materials and anti-static measures during transportation are fully prepared.

• 3: Standard anti-static workbench.

• 4:Use ESD protection trays and diverters.

• 5: ESD static control grounding mat – protect the ground.

• 6: Set up anti-static overalls, anti-static hats, anti-static shoes or anti-static shoe covers for ESD protection workshop staff.

• 7:Operators wear grounding straps.

The generation of static electricity can be seen everywhere, and the randomness and complexity of ESD are uncontrollable.

In the semiconductor device production workshop, due to dust adsorption on the chip, the yield rate of IC, especially very large scale integrated circuit (VLSI), will be greatly reduced. Packaging in the transportation process, damage caused by improper packaging materials during transportation.

![1726293998300975.png FX56`KWFBX[[]$$E4PXKMRO.png](/image/ueditor/php/upload/image/20240914/1726293998300975.png)