-Original content, please do not reprint.

Sample packing should not put humidity card desiccant? Should I use static electricity bag? And how to pack the sample boards of different packages of components? What consequences will be brought about if the sample board is not packed properly? Today we will discuss these issues in detail.

Sample packaged humidity card for use of desiccant

Just a couple sample packages to put in humidity cards and desiccant?For electronic components with high humidity sensitivity, the following packages are generally available: QFP, PLCC, BGA, CSP, SOP, SOJ, QFN, PGA.If they are exposed to moisture, they are likely to evaporate and expand at high reflow temperatures, destroying the chip.But for product prototypes most customers are welding by hand.But for product prototypes most customers are welding by hand.So the welding requirements are not as high as in bulk, so you can decide according to your situation.

Use of static bags

• Static electricity is not less harmful to precision components, it can penetrate the interior of the component to make the internal trigger of the component lock up, or short-circuit.

• In real life, triode samples often do not use electrostatic bags seem not to be electrostatic breakdown,, indicating that electrostatic breakdown is an occasional damage problem, not a high probability or a large number of events, but it is the possibility of occurrence.

• The fact that static bags don't cost that much.In order to give the product a better product quality assurance, even if it is a small probability of events why not go to avoid the occurrence of it?

What tools are commonly used for sample packaging

Our most common sample packing tools

• Sample box, plastic sample box, carton sample box, built-in anti-static protection sponge.For materials without trays or braided tape packaging, samples of 1-6 tablets can be loaded.

• Sample sealing bag, anti-static flat bag, anti-static self-sealing bag, anti-static aluminum foil bag.

• Pallet corresponding to the encapsulated pallet.

• Foam bag, shockproof and pressure-proof cushioning foam bag.

• Desiccant, 5g sachet desiccant, 20g, 30g desiccant, 50g desiccant.

• Packing cartons, samples need to be packed with bubble wrap to fill the empty space in the box, to prevent vibration or heavy pressure on the sample damage.

How about packaging methods for different types of chip packaging samples

Today, I got these packages to share with you.

QFP

• QFP packaged samples are usually in trays, but also in tape and reel, QFP has a high density of feet and is fragile and brittle, as the samples do not have the original packaging or trays.

• Packing this kind of sample is more difficult, nana think it is best to use this kind of sample special sponge packing box.

• In addition to anti-pressure, anti-friction can also be anti-static, QFP samples are very suitable for, in order to prevent the samples of moisture, placed in the sample box and then vacuum.

QFN

• Tape-and-reel samples can be packaged in anti-static self-sealing bags, or in the anti-static sponge boxes mentioned above.

• QFN package type components are mostly tape and reel mounted.

DIP

• DIP package devices are common tube mounted form, the sample board is not enough to cut down the tube.

• Load the chip and then plug the anti-drop plug to prevent the gap is too large chip back and forth friction damage to the chip.

• Finally, use the anti-static bag to seal.

SOP or SSOP TSSOP

• SOP or SSOP, TSSOP package, usually tape and reel, tape and reel samples can be packaged in anti-static self-sealing bags.

• Some of the tubes can be packed in anti-static sponge boxes, or directly in tubes and then packed into anti-static bags after vacuum sealing.

![1731574244996770.png {3T7J%}2%G$V]5]_$}`T_56.png](/image/ueditor/php/upload/image/20241114/1731574244996770.png)

Sample packaging problem

Keep these in mind when packing samples

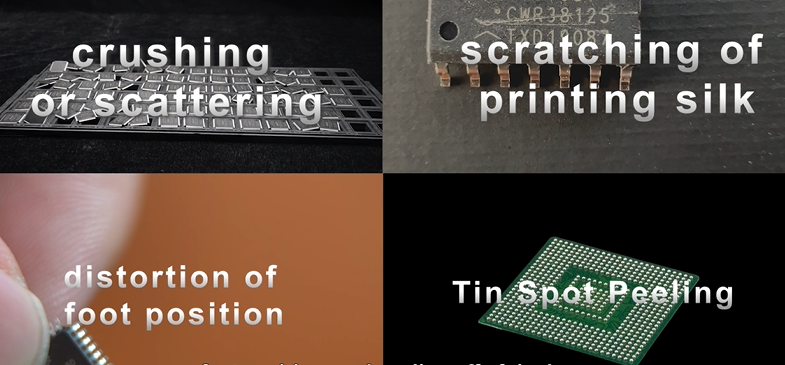

• Bad packing will lead to friction between goods after crushing or scattering, scratching of printing silk, distortion of foot position, and peeling off of tin dots.

• Braided tape without a disk of goods can not be rolled too tight, too tight will be pressed crooked inside the foot of the foot which leads to goods in the hands of customers can not pass the test.

• Vacuum-packed goods that leak may render the feet unusable after oxidization.