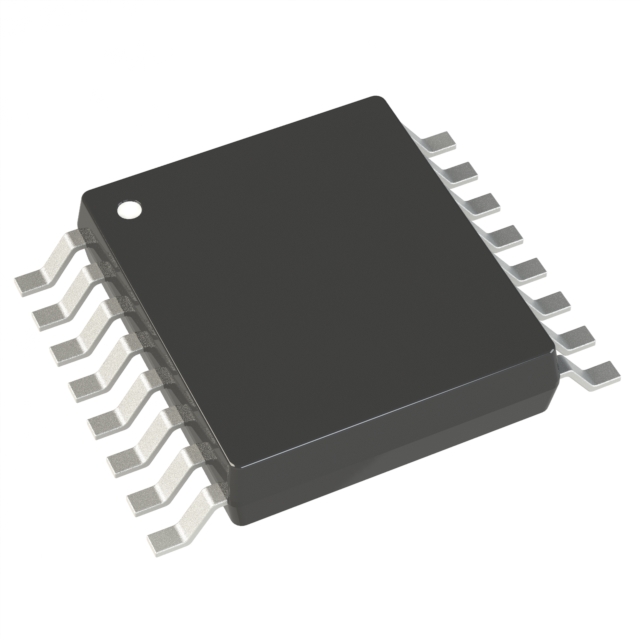

| Chip powder feet and shiny feet |

| Why are shiny feet losing their popularity? |

- Original content, please do not reprint.

Is a shiny chip a fake? What's the difference between a pinky and a shiny one? Why are most chips pinky now? Do the pins of a chip still contain gold?

A chip without pins is like a human who has lost their mouth and ears, unable to communicate or receive information from the outside world. This shows how important pins

are. Some people have better hearing and vision, while others may be nearsighted or have difficulty hearing clearly. Just as the material of the pins on a chip affects its

performance, the quality of the pins on a good chip is also superior.The previous chips were high in gold, with gold wires in the pins and inside. The current chips have much

less gold in the pins, and even some plastic pins are made of material.Of course, the business of collecting chips and refining them still exists, which means that there are some

parts that contain gold chips, but some more or less.

Chip powder feet and shiny feet

A few years ago, there was a way to identify the original chip by looking at whether the chip's feet were pink or shiny.

The main reason is that most chips today use the tin-plated process, which we commonly refer to as the powder foot. Therefore, many people recognize this powder foot.

Some friends might say, are chips with a shiny foot considered outdated? Could they be fake? It's not necessarily so; both types of leads have their own reasons for existence.

The shiny foot chip does not mean it has been completely phased out, as it has better conductivity and is used in many consumer electronics. However, its corrosion resistance

is somewhat inferior, making it more prone to oxidation. Therefore, people later adopted a process called tin plating, which is what we refer to as powder feet. Tin-plated feet

are better suited for applications in electronic devices with higher environmental requirements, such as cars and industrial automation.

Why are shiny feet losing their popularity?

Then why does the lead of our chip look so powdery? Mainly due to a mysterious potion. This additive is called tin chloride plating solution. This mysterious potion causes the

leads to produce very fine and uniform tin grains during plating, which is the source of this frosted effect,

In the past, when we sold chips, we said the shinier the better; the shinier it was, the more authentic it seemed. Nowadays, people are actually afraid of buying such shiny shins;

they have a greater belief in these powder-shiny shins. In fact, there might be a misunderstanding that it is a less advanced process, but in reality, its manufacturing process is

actually more complex and challenging. These powder-shiny shins are actually easier to make.

Then why do these shiny pins, which look more attractive, gradually lose their appeal? The main reason is that while these pins have a more beautiful and smoother surface,

the solder tends to spread easily when welding. High temperatures can affect the quality of the weld, whereas the rough surface of these powder pins helps form a mechanical

bond with the solder. In other words, they have better adhesion and are less likely to spread, making them easier to weld.

It's precisely because the chip pin is so beautiful and smooth that it has become its own drawback. Will this process be phased out? Not necessarily; with the emergence of

new soldering techniques, people may improve the welding performance of tin-plated components, making it very likely that these shiny pins will return to the market.