- 原创内容,请勿转载。

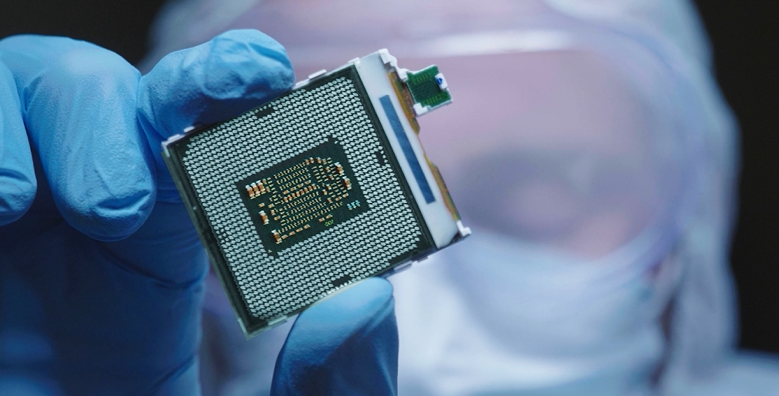

当我们想要识别 1 个或 2 个芯片时,这相对容易,但是当我们想识别大量组件的真伪时,这是一个非常大的挑战

企业。今天,我想与您分享我们长期以来的努力,以确保没有假芯片最终落入我们的客户手中。

源代码管理

• 良好的供应商管理可以杜绝大部分假冒芯片,这既是最低的成本,也是最有效的。像 ICON 这样的公司如何管理

全球 5,000 多家供应商,做一个好的供应商评估吗?这就是我们的业务。

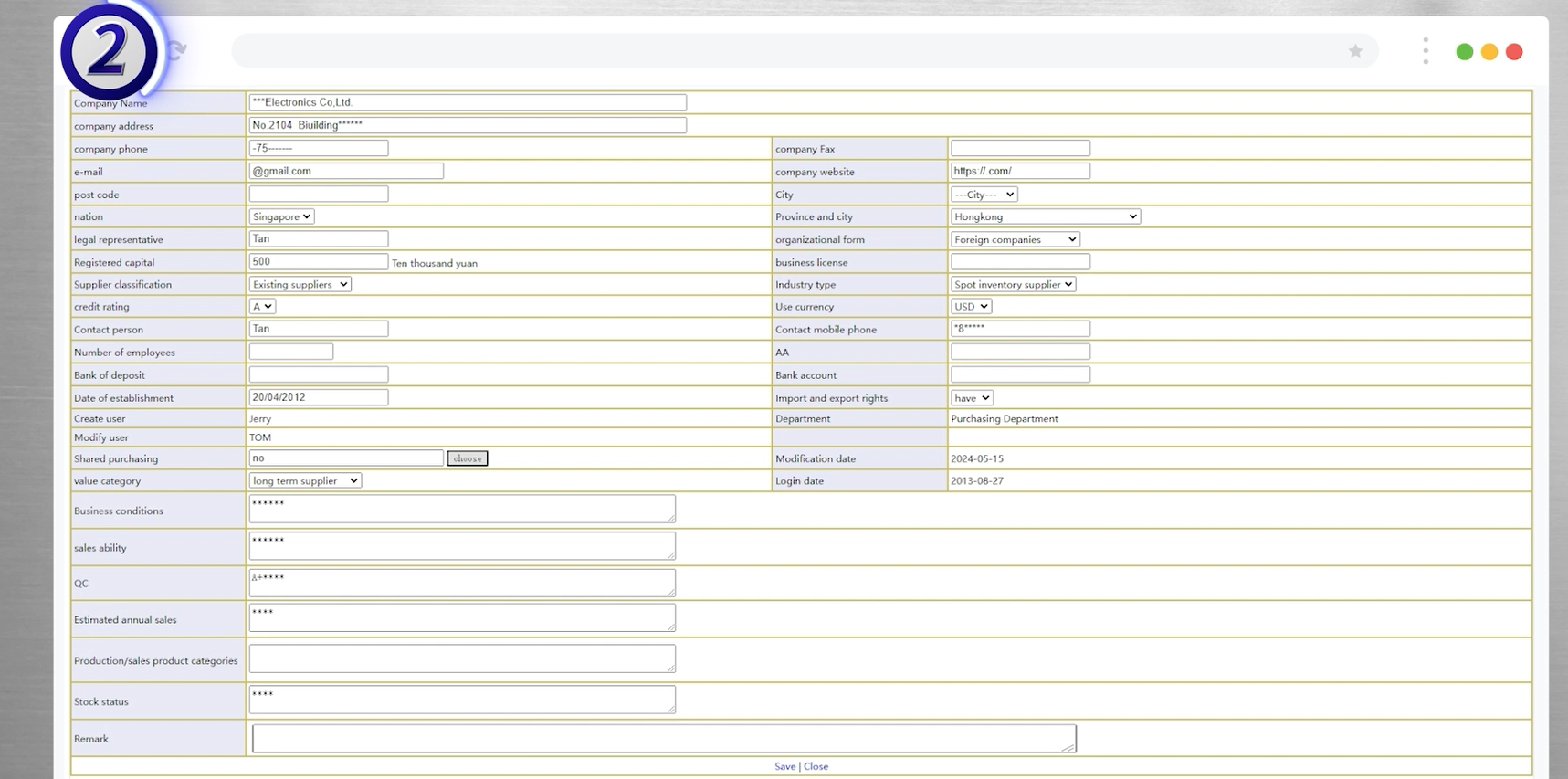

数字化供应商动态

• 随着客户所需组件类型的增加和供应商数量的增加,数字管理和 AI 数据管理是必要的。

• 跟踪长期供应并及时进行调整。我们在系统中记录每个供应商的联系方式,包括准时交货、交货质量和诚实。

这是我们非常重视供应商的一个特点。

• 详细说明公司经营条件的数据。然而,从长远来看,并非每个供应商都是可靠的。我们要求采购人员在

每个供应商的运行状态,动态把控供应商的情况,确保供应商的情况实时更新,使我们的渠道

可控制的。和稳定性。每笔供应商交易都成为我们记录的数据并跟踪其动态,因此数字化管理非常重要。许多公司评估

他们的供应商每年一次。当对方提供假冒芯片时,可能已经有大量假冒元器件进入生产线。我们

Dynamic Data Management 解决了这个问题。

• 筛选出劣质供应商,如我所说 如果您想确保您的供应渠道可靠稳定,那么及时发现并消除不稳定因素就是我们的

的想法来保持通道的稳定性。当我们合作的供应商突然出现问题时,我们会及时将其添加到系统黑名单中以消除

潜在的危机。

• Reliable and rigorous supplier data logging to provide assurance of the origin of our components. We select and configure our inventory or order deployments based on the

reliability level of the channel to ensure that each of our orders is delivered to our customers with the safest and most reliable solution.

• accumulated and updated supplier data provides reliability,Especially during periods of component shortage, a large number of counterfeit and shoddy products will appear.

This is where our huge amount of supplier data will play an important role. If there is a shortage in time, we can also effectively avoid counterfeit and shoddy chips from the

source.

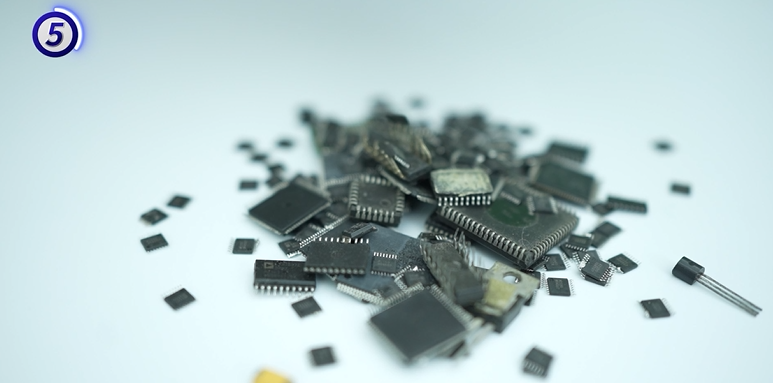

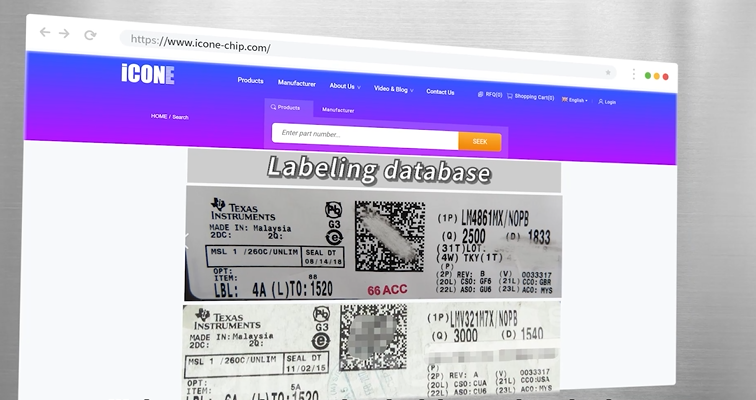

Sample library updated daily

• We also have a key database that plays a role in systematically identifying counterfeit and shoddy components. In the past 12 years, we have handled more than sixty million

chips. The components in the storage will become our gold sample library, providing reliable reference data for the next order. Over time, this sample library has There are more

and more data and they are updated every day, and our reliability is also constantly improving. Since the digital management process is relatively complete, every order we

execute will provide a valuable reference for our next customer. In the past 12years, the customer group we have served has been mainly BOM single supply for small and

medium-sized manufacturers. Currently, we have served more than 3,500 manufacturers.

• small and medium manufacturers demand are frequent and diverse, so this is why our sample library is rich and extremely valuable in identifying fake components. Our

sample library contains original and real chip shapes of various brands of components, integrated circuits, diodes and transistors, passive components, sensors, connectors,

relays, etc.

• One thing you may not know is that the value of fake and shoddy samples may be beyond your imagination. We realize that there are uncontrollable factors in original and

genuine samples. Until you have a sample library of counterfeit components, many truths will be directly displayed in front of you. Many people don’t know that the most

valuable databases are not original and real samples, but fake and shoddy samples.

• We consciously collect a large number of sample libraries of fake components, which is included in the training and screening work of our QC personnel, so our QC personnel

are familiar with the appearance of counterfeit and shoddy components and can eliminate them at the first time, and our library is kept updated to adapt to the constantly

improving counterfeiting techniques of counterfeiters of fake and shoddy components. Including various types of refurbished and scattered new chips, the most difficult to

identify are counterfeit labeled components because they have a brand-new and complete appearance. We have a large number of counterfeit samples of such components,

which provide us with valuable reference for the screening work. Even if you have massive sample data, it doesn’t mean you can detect all fakes.

Tag libraries also have value

• Although labels cannot 100% identify counterfeit components, they have certain reference value. At least it can help us identify some obvious counterfeit components. We

have more than one hundred thousand tag databases. We are also assisting our QC personnel in appearance inspection.

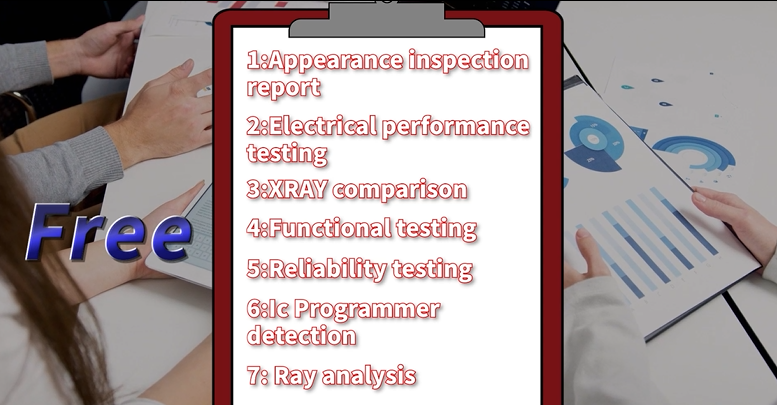

Test reports we can provide

• Since we have been focusing on providing BOM services to customers for 13 years, our sample library contains components of various brands, which can help us effectively

identify fake chips., although there are still a large number of components that cannot be identified through appearance screening, we can still conduct in-depth screening

and analysis of the components through technical ways. Therefore, we can provide customers with the following testing solutions, free of charge at the early stage of the order.

Provided to customers to reduce customer purchasing costs.

Testing plan

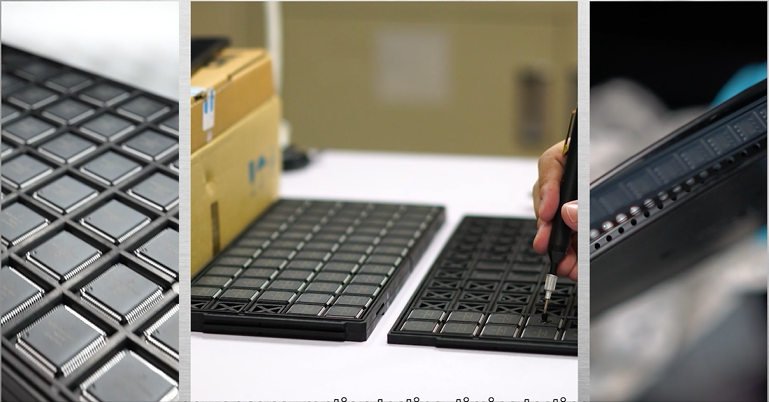

• Our incoming material inspection appearance inspection process includes labels - outer box - internal auxiliary materials - chip MARKING inspection - pin inspection and

wiping - chip body inspection - standard parts comparison.

• Its principle is to test and analyze the electrical characteristics ,of the chip through input and output signals to determine whether the chip can operate normally and

whether there are potential problems. It also includes characteristic testing, power consumption testing, timing testing, etc.

• X-ray comparison: Obtain high-definition X-ray photos of the internal structure of incoming materials ,and compare them with X-ray photos of the internal structure of

standard original parts. This method is suitable for most chips.

• A method of comprehensively testing the functionality of a chip. By designing a series of test cases to cover various functions of the chip and verify the performance of the

chip in different working way, we can understand whether the function of the chip is perfect.

• Reliability testing is to test the chip under different environmental conditions to check the life and stability of the chip. This kind of testing often includes humidity testing,

vibration testing, destructive testing, temperature cycle testing, etc. Through reliability testing, you can understand how the chip performs under various extreme conditions.

• Use tools such as Programmer fixtures and emulators to test components. The software can read whether the component is a genuine model, and perform repeated erasing

and burning operations to check for chip damage.

• The X-ray source emits X-rays and irradiates the chip. Different materials in the chip have different signals such as scattering, reflection and absorption of X-rays. By measuring

these signals, the structure and defect information inside the chip can be obtained.

• We have served many customers who believe in the testing reports of testing agencies. In fact, they do not know that some components are very cleverly counterfeited and

their components can escape many detection methods. Therefore, the combination of real-time and dynamic counterfeit component data is of high value here. In many cases,

for problems that cannot be solved technically, some inadvertent data provide the core help. Of course, for the sake of safety, we provide customers with comprehensive

screening plan. Including appearance screening and in-depth screening combined with technical means.

Additional technical services provided, free programming services

• Our programming services allow electronics manufacturers to outsource the programming of their components to us. This solves the programming costs and consumption

caused by manufacturers due to insufficient equipment or inadequate personnel training, thereby improving the efficiency of the production line and saving costs for the

company.

• Outsource your component programming to us and benefit from lower costs, higher productivity and an integrated supply chain.Fast delivery means you can ensure your

production is completed on time and your time is valuable.