-Original content, please do not reprint.

While people are still talking about whether A.I will threaten human survival, the progress of AI automated equipment has become irresistible. A revolution that is revolutionizing manufacturing is underway quietly, and you may not be aware of it yet. Artificial intelligence is already around you and will soon exceed your imagination.

What is the difference between traditional automation equipment and AI automation?

• Solving simple batch repetitive work and reducing the physical labor burden of employees, these functions of automated production equipment have become a thing of the past. Before the arrival of artificial intelligence technology, these modern technologies seemed to have provided a lot of conveniences for humans, but AI automation equipment can do much more than that.

• The ambition of artificial intelligence goes far beyond just solving the problem of repetitive labor. Those difficult tasks that are not easy to be copied are also what AI is trying to take over, including polishing, cutting, grinding, deburring or other precision mechanical tasks. Only learning robots can handle these tasks.

• Ordinary robots need to write fixed programs to allow them to complete designed actions, such as attaching labels and screwing on bottle caps in fixed work stations. This kind of mechanical program can be replaced by algorithms. Learning robots do not need traditional programming. They need to learn how to make a product by themselves, make mistakes and then collect data by themselves. You do not need to tell it the details and steps of the work, you only need to Tell it what result you want? It does the entire process on its own and knows better than you what mistakes to avoid.

• When you want to complete the production of other products, you do not need to buy a new machine, but let it relearn the production process of another product. Therefore, lengthy programming is no longer necessary, which greatly reduces the role of software engineers.

• Robots or cobots can learn and take over the execution of non-linear processes that are not easily copy。Multi-arm special robot. They can decide on their own which arm to perform which action.

What enables automation equipment to evolve to this extent?

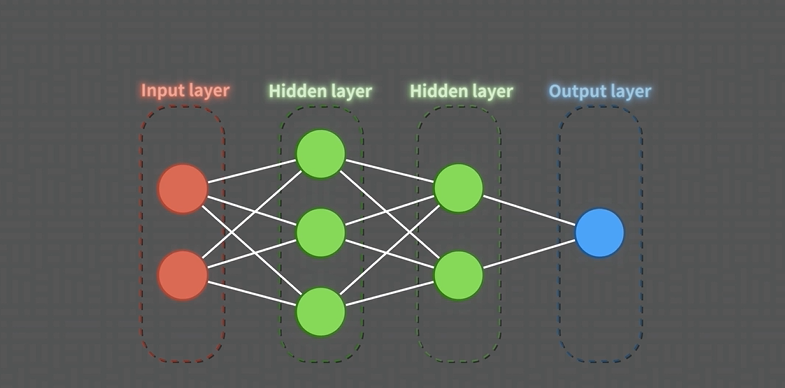

• What enables automation equipment to evolve to this extent?Industry generates large amounts of production data every day. For example, the process of making goods, predictable reasons for product failure or behavior, etc., can be collected and compiled into data to build AI models. The neural network of the human brain inspires artificial intelligence. Each node is also called an artificial neuron and has associated weights and thresholds. If the output of any single node is above a specified threshold, then that node is activated and the data is sent to the next layer of the network.

• Based on this principle, artificial intelligence learning methods can be divided into the following three types. The pros, cons and costs of each learning method are different.

• Its algorithms usually have the following five types.Enterprises can use it to improve production or operational efficiency. The most important thing is to provide very accurate and unbiased training data sets. Otherwise, AI learning that keeps making mistakes will only consume a lot of resources and money, and will also make business owners lose confidence to Keep going.

When a worker's apprentice turns into a robot?

• An amazing fact is that machines can program themselves through learning,If you want it to learn a job, you may need a worker to pick up the robot's arm, teach it to complete various steps or process positions, pick it up or put it down, etc. The machine can even self-correct through its own algorithm, completing better work results and more efficiently than workers, and can work for extremely long hours without the need for vacations.

Multi-arm special robot

• With the help of machine learning, multi-arm special robots do not need to be programmed to set their movements. They can decide the position and direction of their robotic arms and complete their work autonomously. Therefore, if there is a problem with the settings, the robot will lose control and it will be really dangerous for humans.

The biggest benefit of artificial intelligence

• Manufacturing is likely to be the area that benefits the most from artificial intelligence. Manufacturers around the world are racking their brains to use AI to bring them more benefits.

![1722591123106503.png 97[]~A6A~6H7OMUIVO}3OTF.png](/image/ueditor/php/upload/image/20240802/1722591123106503.png)

The explosion of data has put people in decision-making difficulties

• It is estimated that the manufacturing industry generates about 1,812 pb of data every year. The large amount of data does not bring convenience to enterprises, but makes their decision-making more and more difficult and slow. This is also a suitable time for the explosion of AI technology. This phenomenon does not only exist in the manufacturing industry, but also in all walks of life.

twin technology

• When you are learning from a very senior technical worker's experience, and he is serious about correcting your mistakes and teaching you new skills, he may not be a real person, but a person provided by smart AR glasses in an industrial environment training program.

• When you are testing new cutting paths or robotic assembly, you may also find that you are just in a simulated factory,not a real one.Experienced employees can provide on-site guidance to multiple new employees at the same time without having to go to the site.

• Many automated equipment factories are facing the problem of increasingly low profits and difficulty in survival. Either this is an opportunity to transform to AI, or we should think more about when machines can learn skills by themselves and decide where to swing their arms. Will it bring any threats to us?